Materials and Corrosion for Piping and Mechanical Engineers

In-Company

Virtual or Classroom

Upon Request

16hr Content

Custom Scheduling

Steve Paterson

INCO2601

Course Objective

"

To provide piping and mechanical engineers with an understanding of the material science and selection decisions for metallic pressure equipment.

"

Private course for team

Custom scheduling

Industry Expert

On-site or virtual

1-year access

to recordings and modules

Receive Personal Certificate

and prove your knowledge

About the course

In-Company

Live sessions

16hr content

Custom

English

INCO2601

Piping and mechanical engineers are regularly involved with metallic piping and pressure vessels. Typically the material selection is as defined by the material specialist in the design specification. The engineer is entitled to ask though, why this material selection? is this material susceptible to corrosion or fatigue? how should the integrity of the material be managed?

This training course aims to give engineers an appreciation of different types of metallic materials, for example what are the differences in micro-structure, what is the effect of heat treatment, and why is a certain metal susceptible to a specific failure mechanism. With the key outcome being piping and mechanical engineers who can pose the correct questions related to material selection and have the awareness to act proactively should they identify a risk.

During this course participants will learn about the decisions that are taken in material selection, from material properties and which design codes define the material composition, to how does the material selection play a key role in reducing the risk of failures due to corrosion and vibration. Cases are included to explain examples of typical in-service failures, followed by an overview of the principles of quality assurance, quality control and integrity management as applied to materials.

The course consists of 16hrs of online live sessions with the instructor. All training content is provided through your EngineeringTrainer account.

After the course you maintain 1-year unlimited access to the course, including any new course material. This allows you to perform modules again should you need to refresh your knowledge.

Meet your instructor

Steve Paterson

Materials and Corrosion Advisor and Trainer

Materials, Corrosion, Welding, Inspection

Program & Details

Different types of crystalline structures, metallic bonding and dislocation theory principles

Physical and mechanical properties (tensile, hardness, etc) of materials and type of testing. Specification of materials

Methods of manufacture including casting, forging, rolling, extrusion, pipe manufacture, HIP, additive manufacturing

Iron carbon-phase diagram, microstructures in steel and the effect of heat treatment

Different types of stainless steels and nickel alloys commonly used, including the influence of alloying and microstructure on properties

Overview of common corrosion and stress corrosion mechanisms experienced in oil and gas and energy transition sectors

Explanation of the typical approaches that can be used to mitigate corrosion and stress corrosion

Fundamentals of vibration fatigue and fracture and other mechanical mechanisms such as wear

Explanation of the typical approaches that can be used to mitigate corrosion and stress corrosion

Explanation of the typical approaches that can be used to mitigate corrosion and stress corrosion

Difference between quality assurance and quality control, impact on materials and examples of implementation

Principles of failure investigation, including examples of common failures in oil and gas and energy transition sectors

Overview of common inspection methods including limitations and optimal application areas

Principles of systematic management of integrity in relation to materials and degradation mechanisms

Results

After this course, you...

-

understand the difference in properties between the different metallic materials, and how these are related to the microstructure of a material

-

are familiar with the different material manufacturing methods, and have seen how additives and heat treatment can be used to influence material properties

-

have been introduced to the common corrosion, stress corrosion and mechanical degradation mechanisms and the typical mitigation methods

-

know the principles of welding metallurgy and welding quality control

-

are aware of common failures and the principles of a failure investigation in the oil and gas, and energy transition sectors

-

understand the different NDT approaches, and the optimal application areas for each approach

-

have seen the principles of integrity management for metallic materials

Who should attend this course:

-

Piping and mechanical engineers who want to gain an understanding and appreciation of material selection and material management for piping and pressure vessels.

Prerequisites:

-

Affinity with the design of piping and/or pressure vessels.

Level: Beginner to Intermediate

Live sessions

This course consists of instructor-led group sessions, these group sessions can be Virtual or Onsite. During these sessions participants can ask questions to the instructor which are discussed, as well as questions submitted beforehand in the learning portal.

After each live session used slides and exercise documents are made available to participants on the learning portal.

Please note that for privacy reasons no recordings of the live sessions are made or provided.

You receive 1-year unlimited access to the course. This allows you to watch content again if this is beneficial for your daily work activities.

The sessions are scheduled together with the customer and are private for their team only.

Typically the training course would be scheduled as:

-

Virtual: 8 sessions of 2 hours

-

Onsite: 2 days of 8 hours

Though there is total flexibility to customize the training program.

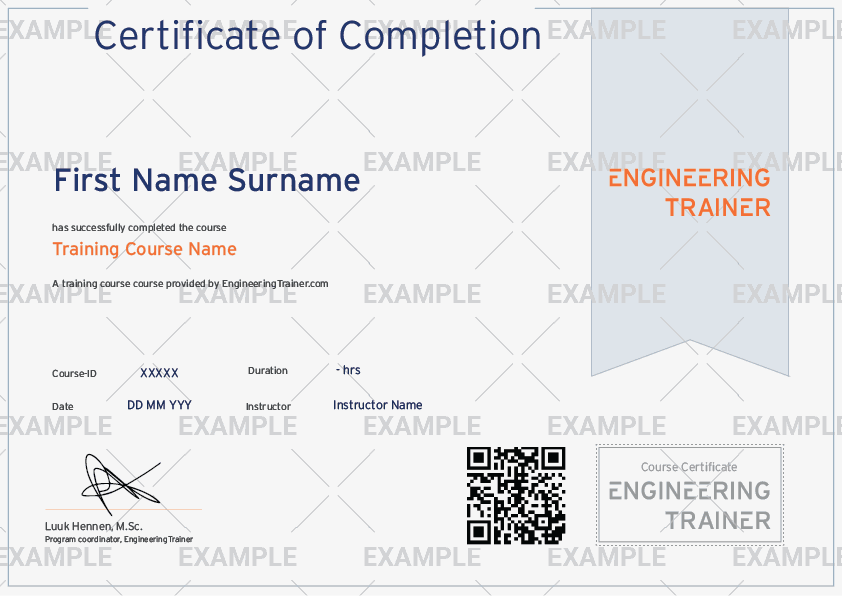

A personal digital certificate will be made available to each participant upon full attendance.

Example Certificate:

FAQ

This course consists of instructor-led live sessions which consist of presentations, demonstrations and discussions of questions. During each live session participants can ask questions to the instructor (through chat or microphone) which will be answered.

Please note that for privacy reasons no recordings of the live sessions are made or provided.

The training material used in the live sessions, for example the slides or exercises, will be available in the EngineeringTrainer portal for a year after the date of the training allowing you to refresh your knowledge or review material if needed.

No, course content is not available for download.

The training material used in the sessions, for example the slides or exercises, will be available in the EngineeringTrainer portal for a year after the date of the training allowing you to refresh your knowledge or review material if needed.

Please note that for privacy reasons no recordings of the live sessions are made or provided.

Yes, interactive Q&A sessions are part of the live sessions in this course and allow you to interact with the instructor and ask questions.

To respect the privacy of the participants the live sessions will not be recorded, and as such the live sessions cannot be played back. Therefore it is important for all participants to block the time slots of the live sessions in their calendars and be present.

No software licenses are provided as part of this course.

Yes, this course qualifies for PDH hours as per the NCEES CPC Guidelines.